Getting a Head Start

You might not be too concerned about the quality of wastewater that comes into your plant because your goal is to meet permitted levels on the way out. It’s not like you have a lot of control over what’s coming through the collection system anyway.

Think about this, though: what if you could improve the quality of wastewater throughout your system? Wouldn’t it make your job easier if the wastewater bacteria in your plant could more quickly break down organic material and remove harmful nutrients such as nitrogen and phosphorous before you blast them with costly chemicals?

Here’s a look at how you can use your entire collection system as a giant bioreactor, and improve the way you do nutrient removal.

What is rbCOD?

A common measure to determine the amount of pollutant load coming into a wastewater treatment plant is Chemical Oxygen Demand (COD), which is a measure of the oxygen-consuming capacity of inorganic and organic matter present in wastewater. COD is expressed as the amount of oxygen consumed in mg/l.

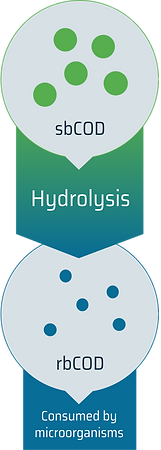

A part (usually 10 to 20%) of the COD is readily biodegradable (rbCOD): the small molecules, such as volatile fatty acids, alcohols, amino acids, and simple sugars that are directly available for biodegradation by the bacteria present in wastewater. Another part is slowly biodegradable COD or sbCOD, which are larger molecules than rbCOD. They need to be broken down to rbCOD via hydrolysis first, and then can be consumed by microorganisms. Because hydrolysis processes are typically slow, sbCOD needs more time for degradation and conversion to rbCOD.

1

Why is rbCOD important?

Nitrogen and phosphorus removal are two of the most important tasks of any wastewater treatment plant, and rbCOD can be a valuable ally in the process. Biological nutrient removal is accomplished by a unique set of bacteria (nitrifiers, de-nitrifiers, phosphorous accumulating organisms/bacteria) through a series of reactions – specifically nitrification and denitrification under aerobic, anoxic, and anaerobic conditions.

Plant operators need these reactions to function efficiently so they can minimize the amount of nitrogen and phosphorus discharges, allowing them to meet EPA permit requirements. A lack of sufficient rbCOD will result in a poor denitrification performance even when other conditions necessary for the denitrification reactions are present: sufficient reactor volume, enough specialty denitrifying microorganisms, and optimum levels of dissolved oxygen in the aerobic basins. In short, you have to have enough food, available quickly enough, and easily digestible for the “bugs” to do their work.

Average unit capital cost for biological nutrient removal upgrade for a small- to medium-sized treatment plant

To remove an acceptable amount of nitrogen and phosphorous, treatment plants spend a lot of money on nutrient removal. A report released in 2007 (USEPA, 2007)1 concluded that the average unit capital cost for biological nutrient removal (BNR) upgrade was $1,742,000 per million gallons per day (MGD) for a small-to-medium sized treatment plant (with capacity from 1 to 10 MGD). As part of the nutrient removal operations, treatment plants purchase, install, and deploy technology that dispense chemicals such as ferric chloride, Micro C, or other external carbon sources.

1

How an rbCOD strategy pays off

Instead of heavy chemical dumps and expensive equipment, there are other, less expensive ways to increase rbCOD coming into the plant. An inexpensive, green way to do this is to rely on the entire collection system to make rbCOD, even while the wastewater is on its way. If you think of your collection system as a giant bioreactor, it is possible – through continuous addition of beneficial bacteria – to convert more of the COD to rbCOD using all of the retention time the collection system provides. It’s exactly like giving probiotics to the sewer system.

Once all of that beneficial rbCOD hits the plant processes involved in denitrification and/or phosphorous removal, the reactions happen much more quickly, and removal of N and P is much more efficient because the microorganisms responsible for these tasks are thriving with such a huge boost in readily available nutrients. For phosphorous removal in particular, the biomass that settles in the clarifiers is more efficient at the re-uptake of phosphorus. Plant operators can optimize phosphorus removal by wasting sludge while the bacteria are still holding the maximum amount of phosphorus (for example, plant operations can achieve an SRT of 2 days in the Anaerobic zone of a Modified Bardenpho process).

One plant operator discovered that a dramatic increase of rbCOD in his system caused a dramatic decrease in the chemicals used for the BNR process. He saved enough in CAPEX and OPEX expenses to more than cover the cost of the “good” bacteria addition, which helped him consistently stay well below required state permit levels for phosphorous.

By utilizing this system-wide bioreactor to build rbCOD levels in the plant inflows, you’re making it easier for your plant to meet regulatory levels for phosphorus and nitrogen, while reducing the need for additives and expensive retrofits.